Specialised Laser Products was formed in 1995.

We are ISO9001 and CE BS 1090 accredited

See the services we offer and download our brochure

Read that latest news here at

SLP.

Send your enquiries to our dedicated team.

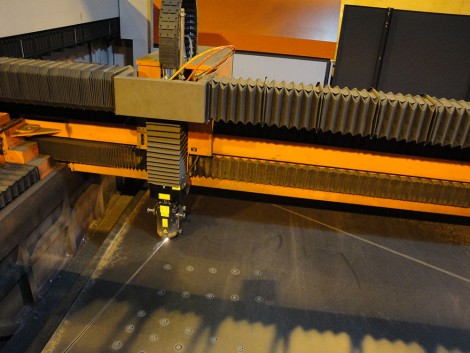

Laser Cutting

Mild & Structural Steel Laser Cutting

At SLP, we hold appropriate levels of mild steel in stock.

We stock and laser cut a wide range of Stainless Steel sheet.

Stainless Steel 420 Laser Cutting

We stock and laser cut a wide range of Stainless Steel sheet.

We laser cut Spring Steel for a multitude of applications.

We laser cut a wide range of Aluminium sheet and plate.

Secondary Processes

Full state of the art bending folding capability.

Precision drilling and tapping ensuring exact tolerances.

Small to large scale fabrication and welding processes.

Superior finish polishing and abrasive grinding.

Machine punching, forming and shearing technologies.

Full CNC multi axis capabilities offered for all contracts.

Galvanising, zinc, nickel, chrome and tin treatments.

Machines Capacity

Our state-of-the-art laser cutting machines enable us to cut a wide range of materials

Engineering, construction and others.

Agricultural products supplied on a global scale.

SLP provide laser cutting for the construction sector.

A vast range of metal sheet applications all being laser cut.

A vast range of metal sheet applications all being laser cut.

All types of laser cut metals for a wide range of industries.

Precision medical equipment for use in critical applications.

Multiple rail industry products using precision laser cutting.

Company News

Specialised Laser Products

Contact Us

Head Office

Unit 6 Ford Park

Canklow Road

Rotherham

South Yorkshire

S60 2JB